Schedule Appointment

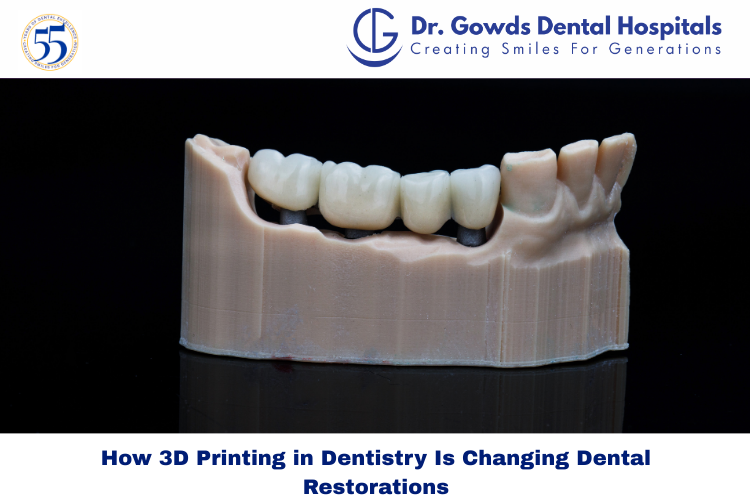

Imagine walking into a dental clinic with a damaged tooth and walking out the same day with a perfectly crafted crown. No messy impressions. No long waits. Just precision, speed, and comfort. Thanks to 3D printing in dentistry, that’s not a futuristic fantasy—it’s today’s reality.

This breakthrough technology is transforming how dentists approach treatment planning, restorations, and patient care. Let’s explore how crowns, bridges, and other key dental components are being reinvented using 3D printing.

The 3D printing in dentistry is the use of additive manufacturing techniques to make dental structures directly from the digital scan. Instead of manually crafting prosthetics or waiting on a lab turnaround, dentists and technicians can now create design, print and place with remarkable speed and accuracy.

From crowns and bridges to alignment, dentures and surgical guides, 3D printing enables individual dental care that is suitable for the anatomy of each patient.

Traditional crowns take days or weeks to produce. With 3D printing in dentistry, patients can receive crowns and bridges within hours—often in a single appointment.

Digital impressions and computer-aided design (CAD) tools eliminate human error. The result? A near-perfect fit and better patient comfort.

No more goopy molds or multiple fittings. 3D-printed restorations are built from high-resolution scans, ensuring a seamless fit from the start.

Once the equipment is in place, 3D printing cuts down on lab and material costs, making advanced treatments more accessible.

Less material waste and reduced shipping mean sustainability in the dental space.

When you wait for a permanent one, there are days of temporary crown. The 3D-affected crown can be custom-built in the same journey. Materials, such as resin or ceramic composite, provide power, aesthetics and a natural teeth appearance.

The bridges require accurate alignment with adjacent teeth. With 3D printing, bridges can be designed with digital accuracy, leading to rapid placements and better long -term results.

3D printing enables dentists to manufacture clear alignment in-house. Each tray is properly mapped into the patient’s digital model, allowing rapid delivery and clever orthodontic improvement.

Implant procedures are highly benefited by 3D-professed surgical guides, which improve placement accuracy, reduce surgical risks, and increase treatment results.

Full and partial dentures can now be printed with high-speed resin printers, allowing patients to provide faster, more comfortable solutions than traditional methods.

The 3D models help dentists explain treatment options, showing patients before and after scenarios, and improve the patient’s understanding and consent.

As a patient, you might wonder what all this tech talk means for you. Here’s the answer:

Yes. The 3D-affected dental materials are biocompatible and safe for intraoral use. Technology is FDA-influenced and already widely adopted in major dental clinics worldwide. Dentists receive special training to operate and check 3D printers for optimal results.

The Future of Digital Dentistry

3D printing is just one part of the bigger picture—digital dentistry. As artificial intelligence, machine learning, and automation evolve, you can expect:

3D printing in dentistry is not only making processes rapidly – it again defines how care is distributed. Whether it is preparing a new crown, planning implant surgery, or improving denture comfort, this technique is strengthening dentists and increasing the results of the patient.

At Dr.Gowds Dental Hospital, we embrace innovation to provide you with the most comfortable, accurate and advanced treatment options. Your smile is nothing less.

Yes, 3D-printed dental materials are biocompatible and FDA-innovative for intraoral use. Dentists undergo special training to ensure that the process is safe, clean and effective.

Based on the setup of the clinic, most 3D-affected crowns and bridges can be designated, printed and fit in the same appointment in a single day.

Absolutely. Modern resins and ceramics used in 3D printing provide high strength, aesthetics and longevity, when maintained properly compared to traditional restorations.

No dirty impression! 3D printing uses digital intraoral scanning, which is faster, more comfortable and more accurate than traditional molds.

Not necessarily. While the initial tool is an investment for clinics, 3D printing lab reduces fees and turnaround time, causing treatment to become more cost effective for patients in the long run.